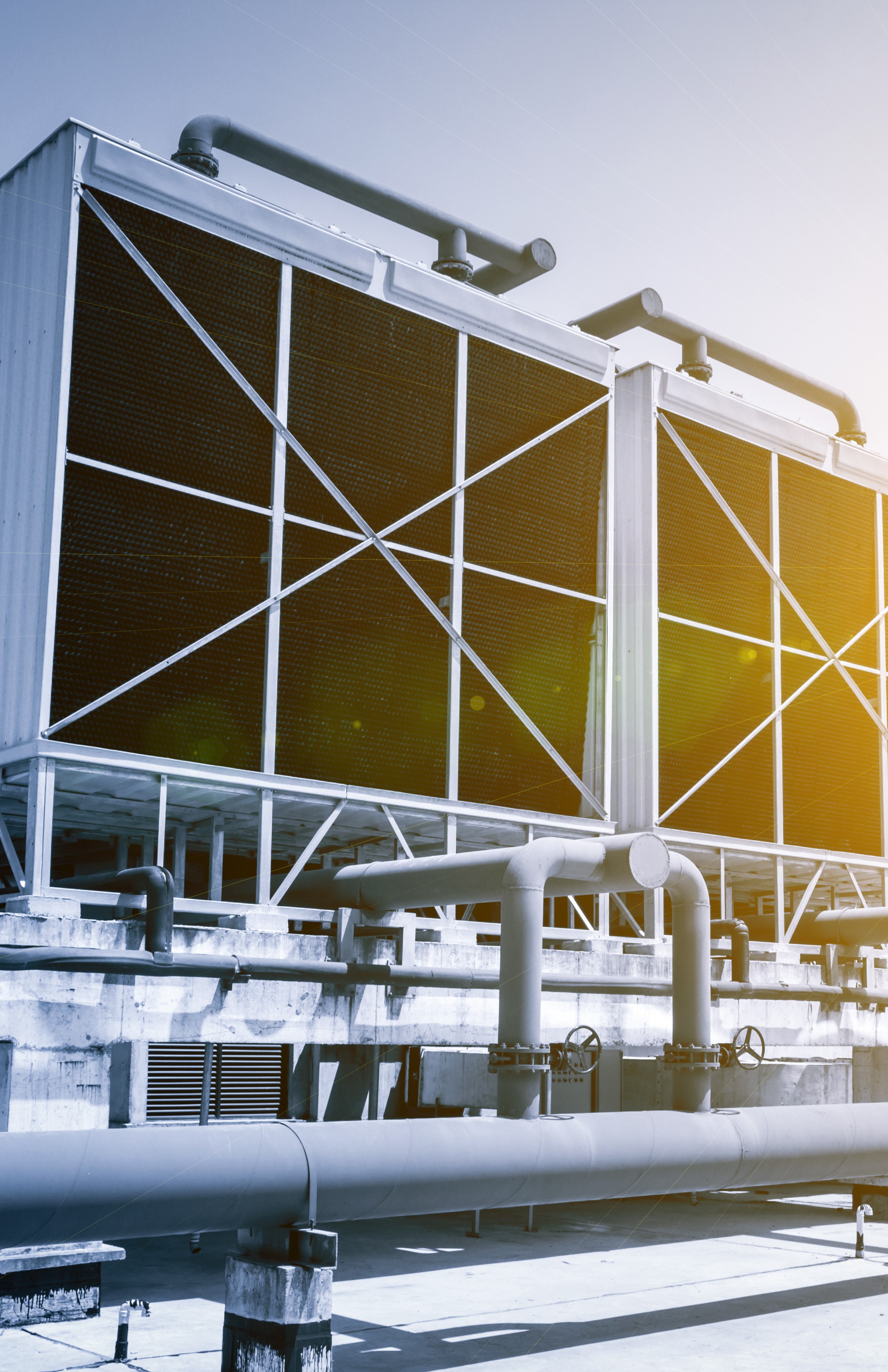

ARC - making cooling more energy efficient

ARC (Automated Response Command) is our market-leading technology that optimises cooling loads of packaged commercial and industrial chiller plant.

Built from the ground up, the ARC software monitors and optimises cooling loads to deliver significant reductions in electrical consumption. This is achieved whilst maintaining existing process and comfort cooling performance.

ARC delivers electrical energy savings of between 8 and 20%. As cooling can account for up to 60% of a commercial building’s energy consumption, the savings ARC can deliver are impressive. Especially considering that with global temperatures continuing to rise, chillers will be expected to run harder and for longer to meet the increasing demand for cooling comfort and process cooling.

For organisations looking to drive down their energy usage and minimise their carbon footprint, ARC will provide fantastic energy savings.